|

|

|

furnace

combustion systems |

|

|

|

|

|

|

|

Furnace Combustion w/ Control Components |

|

| We most commonly install Eclipse Thermjet

burners on furnaces. The Thermjet is an industrial burner

ideally suited for glass melting furnaces for a number

of reasons. Most importantly Thermjets provide a wide

turndown ratio of 50:1. This means the gas/air ratio can

be adjusted to stay in proper proportion from minimum

to maximum output over a broad range. Proper air/gas

mixture ratios are important to fuel efficiency. |

|

| These burners are also designed to promote

good circulation inside the furnace. They are designed

to accommodate National Fire Protection Agency approved flame safety systems and

are delivered with a spark plug and port for a U.V. sensor.

The burner we recommend also has stainless steel internals

and can be operated with preheated air. |

|

| These burners require forced air provided

by a combustion air blower. The industry standard for

many years has been to use a fixed speed blower and control

the air volume with a mechanical butterfly valve via

the temperature control. In many cases this is the best

option; however, for the past 20 years we have been

using variable speed blowers. With a variable speed blower,

the speed of the blower is controlled by the temperature

control. This results in a considerable savings in electric

consumption. |

|

| We also recommend utilizing one blower

for furnaces and a separate blower for glory holes and

other gas/air fired equipment. This results in further

cost savings as the blower for the glory holes can be

shut down during times the glory holes are not in operation. |

|

|

| There are usually two systems that support

a burner. The first is the control system. The control

system can be manual but most commonly utilizes a programmable

temperature control. The second system is the flame safety system that monitors

the burner flame. |

|

|

| Our most common systems are listed below. Please call for specific applications.

We will be happy to work with you and design a system

to meet your needs. |

|

|

| All systems provided by HUB are delivered

with installation and operation instructions. We also

provide training in the operation of new equipment, ongoing

assistance and technical support. |

|

| We carry far more

parts than are listed. Please call us if you

don’t see what you’re

looking for. |

|

|

|

| Eclipse Burners |

|

The Eclipse ThermJet burner uses staged

air & gas mixing to provide a wide turndown range—50:1, the lowest emissions in the industry, and the

highest operating velocity available. Listed are burners

with stainless steel internals for 300–799° F preheated combustion air. |

|

| Call for more information. |

|

| TJ015 150,000 BTU—Contact us for a quote. |

|

| TJ025 250,000 BTU—Contact us for a quote. |

|

| TJ040 400,000 BTU—Contact us for a quote. |

|

| TJ050 500,000 BTU—Contact us for a quote. |

|

|

|

|

TJ025 250,000 BTU |

|

|

|

| Blowers |

|

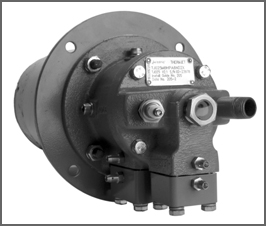

Blower —Typical Cost $1,212.00

In enclosure w/ intake filter.

Various types of blowers are available.

Call for specific pricing. |

|

|

|

|

|

| To Top Of Page |

|

|

|

|

|

Combustion Control

& Safety Packages |

|

Single Burner w/ Variable Speed

Blower

Control Package—Contact us for a quote.

Includes all parts necessary for programmable

temperature control: control, control enclosure, thermocouple,

thermocouple connection wire, ratio regulator, butterfly

valves, Honeywell modulating motor, metering orifice valve, and variable speed blower. |

|

| Flame Safety Package—Contact us for a quote.

Includes all parts necessary to meet National Fire Protection

Agency guidelines: control panel, dual solenoid valve, hi/low

gas switch, air switch, high limit temperature control, thermocouple

ignition, transformer, and blower interlock.

|

|

|

|

Electric Furnace

Heating Packages |

|

| To better meet our customers’ needs, we have decided to add electric packages as an option for furnace heating. The furnace is our same tried and true free standing crucible design with moly disilicide elements instead of a burner. |

|

| We have selected Duralite as a vendor for these packages. Duralite has been providing electric heating systems since 1946 and has experience in the glass melting field. They offer options that are very safe and extremely reliable. We welcome your inquiries about our electric furnaces, and we would be happy to answer any questions and provide you with a quote. |

|

| MU50—Contact us for a quote. |

|

| MU100—Contact us for a quote. |

|

| MU200—Contact us for a quote. |

|

| MU300—Contact us for a quote. |

|

| MU500—Contact us for a quote. |

|

| No furnace system should be operated without proper training and safety precautions. We are committed to safety. Our transformer system provides galvanic isolation—there is no direct connection between the power line and the heating element. The result is a system that has no significant voltage difference versus ground. This means that you cannot be shocked. |

|

|

|

|

Combustion

Remote Flame Safety & Control Panels |

|

|

Eclipse Flame

Safety Panel

& Protection

Control Flame Safety Panel |

|

|

|

| Giberson Burner Packages |

|

150,000 BTU Giberson Burner/Venturi

w/ Venturi, .5" needle valve, ball

valve and gauge.

Contact us for a quote. |

|

150,000 BTU Giberson Burner/Forced

Air

w/ squirrel cage blower, needle valve,

ball valve and gauge.

Contact us for a quote. |

|

Baso Valve and Pilot Safety System

for 150,000 BTU and under.

Typical Cost—$ 480.00 |

|

Other sizes & configurations available.

Call

for more info. |

|

|

| |

| Recuperators |

|

| Recuperators use exhaust gas to preheat

combustion air. They are a great solution to deal with rising

energy costs and increased concern over reducing waste. |

|

We have been using a simple design since 1986, and customers who have switched from a brick flue to

a recuperator claim a 30% energy savings. This is a true exhaust

gas recuperator that preheats combustion air with exhaust gas

only after it has left the furnace interior.

|

|

The design is very simple. There

are no small passages to keep clean and very little combustion

air pressure drop. It actually stays cleaner than a brick

flue thus reducing maintenance. |

|

| We highly recommend recuperators

on new furnaces and will be happy to help retrofit one to an

existing application. In many parts of the country, energy

companies will offer incentives for upgrades that reduce consumption. |

|

| Recupar—$ 1,760.00 |

|

|

|

| To Top Of Page |

|